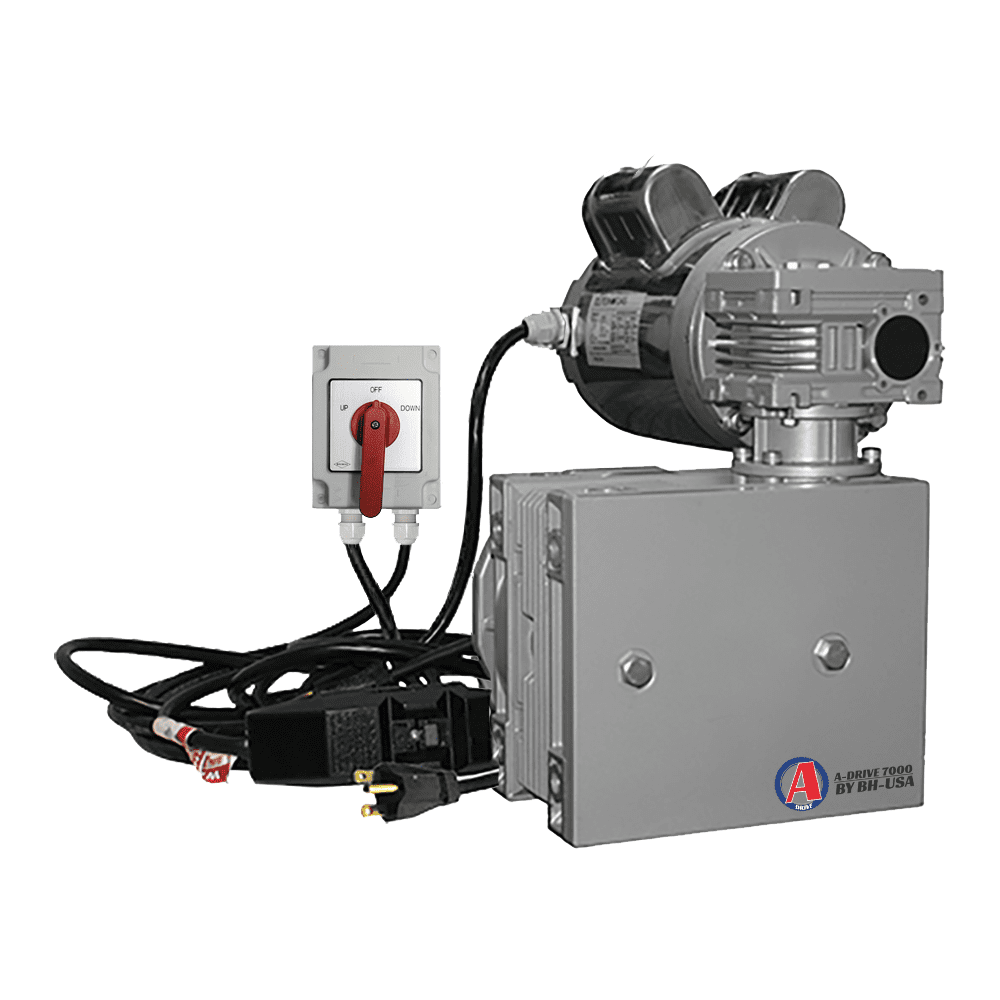

7,000 lb. A-Drive Boat Hoist

- Features the 40:90 double worm reducer gearbox

- Includes 1 1/2 HP electric motor

- 7,000 lbs. straight-line capacity

- Enclosed and specially-blended lubrication

- Made from solid aluminum

- Features all stainless steel mounting fasteners

7,000 lb. A-Drive Boat Hoist

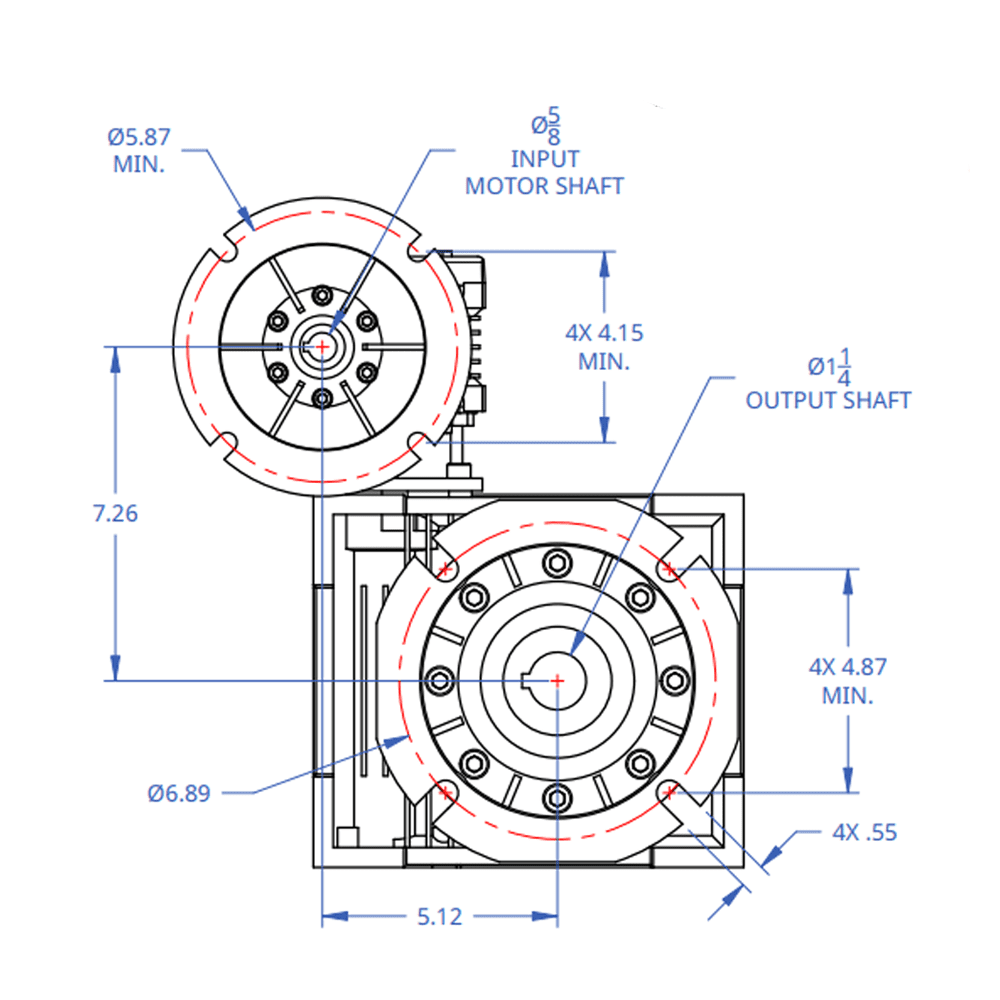

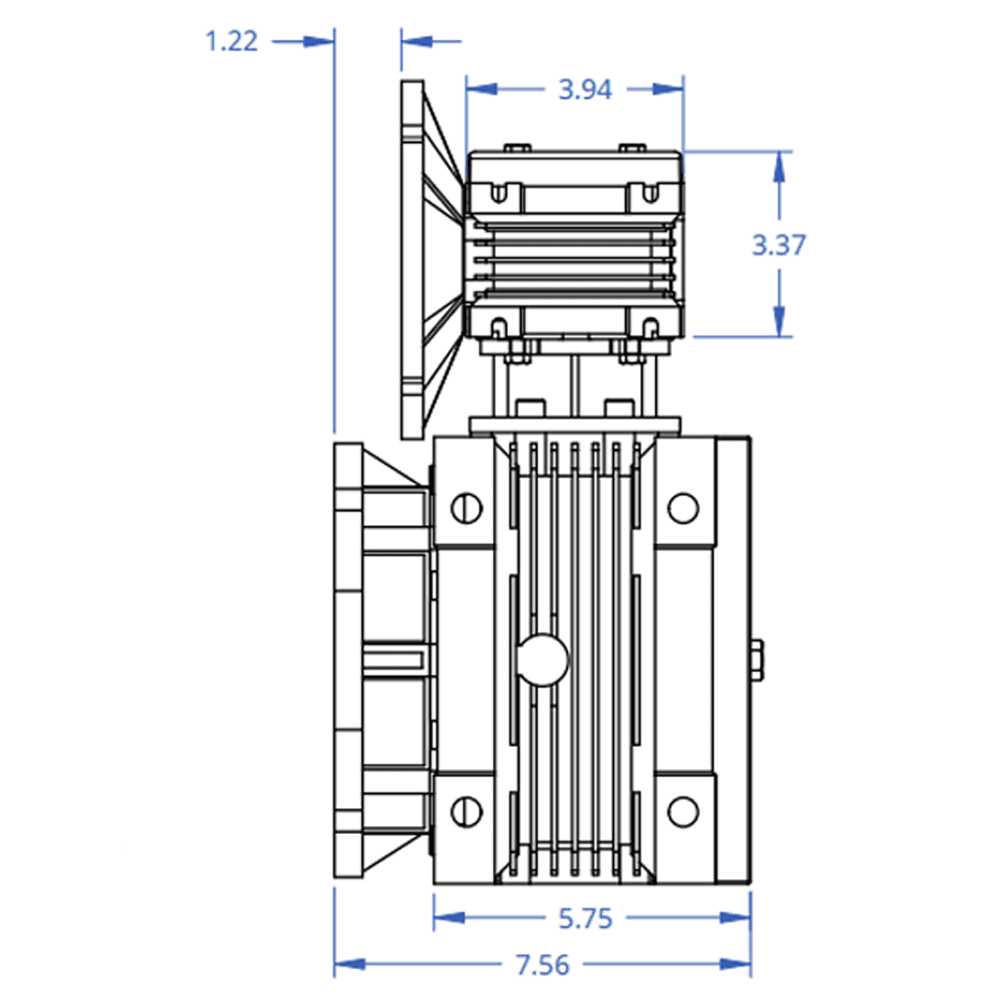

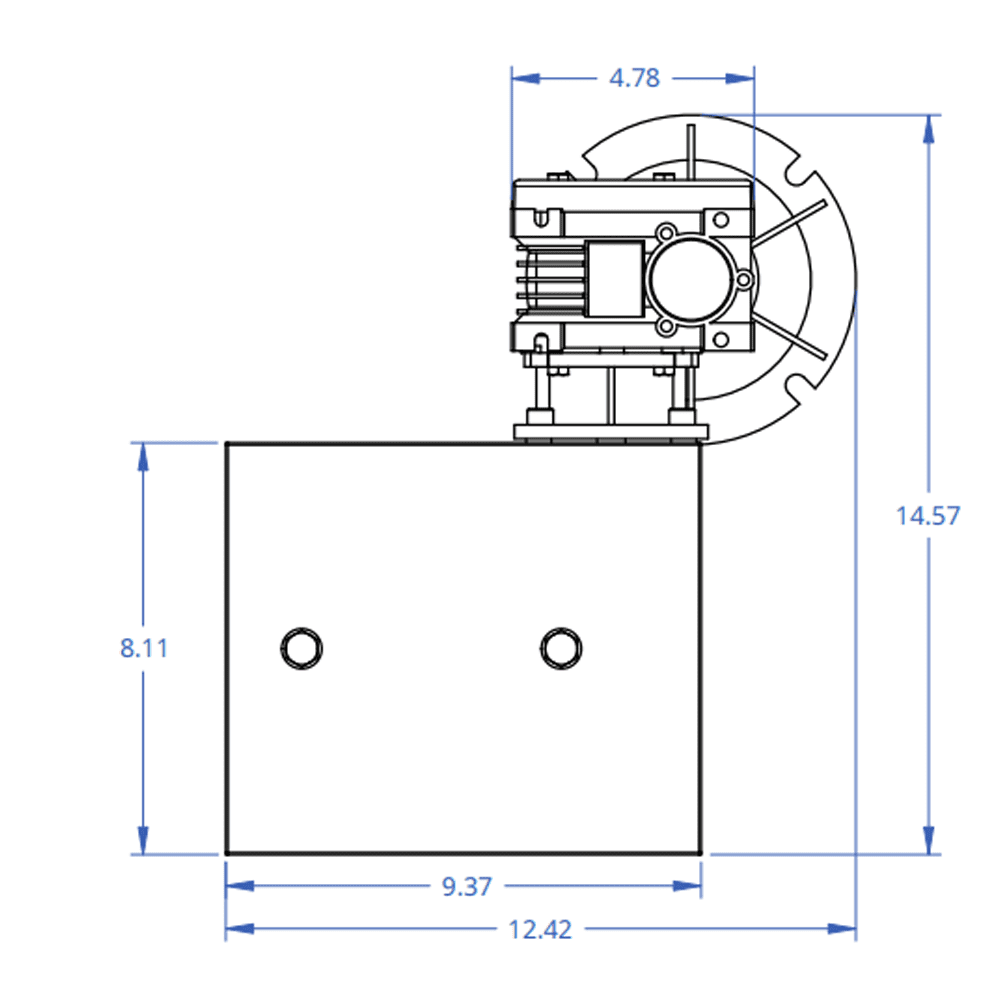

This 7,000 lb. A-Drive Boat Hoist comes with an Elite 1 1/2 HP stainless C-Face wired boat lift motor and an A-Drive 40:90 double worm reducer gearbox. The gearbox housing is made of solid aluminum with a marine-grade finish. It has a 7,000-lb straight-line capacity. Gear ratio: 450:1. Factory lubricated with a special blend of gear oil. Seals can be replaced. The gears do not freewheel. We have partnered with one of the biggest worm gear reducer manufacturers in the world. Easy installation with optional hoist mounts The motor is equipped with an in-line GFCI, wired for 110v or 220v, and 16 ft. of control cable.

This reducer gearbox utilizes a double worm drive reducer. The 7,000 pound BH-USA A-Drive boat hoists are equipped with this gearbox. A marine-grade finish is applied to the solid aluminum construction. Bronze-on-steel gears are used in the gearbox, which has a gear ratio of 450:1. Cast aluminum is used for the motor and drive pipe flanges. Throughout the double-worm reducer, stainless steel fasteners are used. To mount the drive pipe on the reducer gearbox, a hardened drive shafts required. They are not included with this gearbox. When the appropriate mounting plate is used, this gearbox can be used on both overhead boat lifts and pile-mounted boat lifts. Hardened output driveshafts are required to attach the direct drive boat hoist to the boat lift drive pipe.

The Elite 1 1/2 HP Stainless C-Face Electric Motor are single phase, dual-voltage motors. It comes from the factory wired at 220v, but a licensed electrician can convert the wiring to make it a 110v electric motor. Made from stainlesss steel. The NEMA 56 shaft is 0.625 inch thick and 1.88 inch extruding from the motor housing. UL Recognized (C-UL-US). It uses a capacitor to start.

TENV (totally enclosed, non-ventilated) housing. TENV housing prevents dirt, insects, and water from entering the motor. 15 minutes maximum runtime. Includes 1 inch long x 1/4 inch wide keystock, colored T-wires, easy-to-follow wiring instructions, BH-USA equipment guide, and wiring instructions. A motor wire harness is installed directly on the electrical motor. Depending on your preference, you can select a maintained (lock-on) or momentary (spring-loaded) drum switch type. The in-line GFCI has a built-in test and reset button.