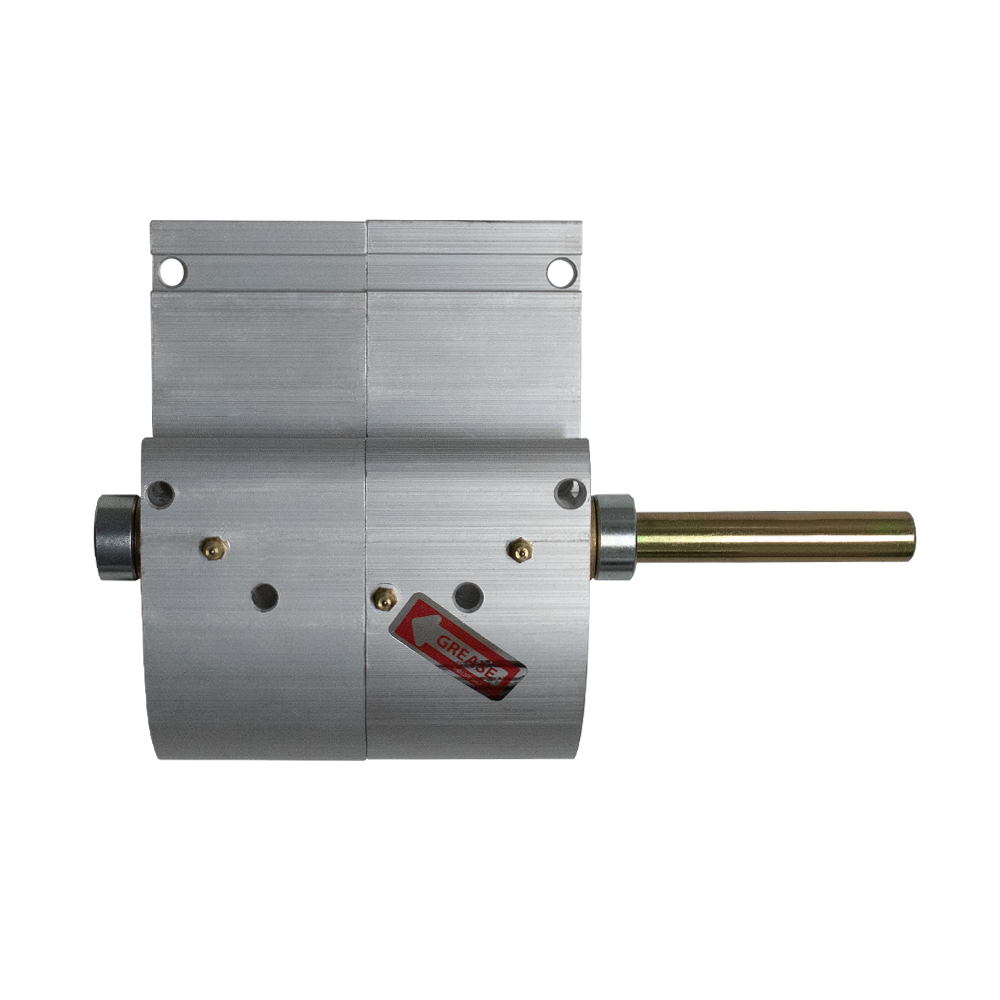

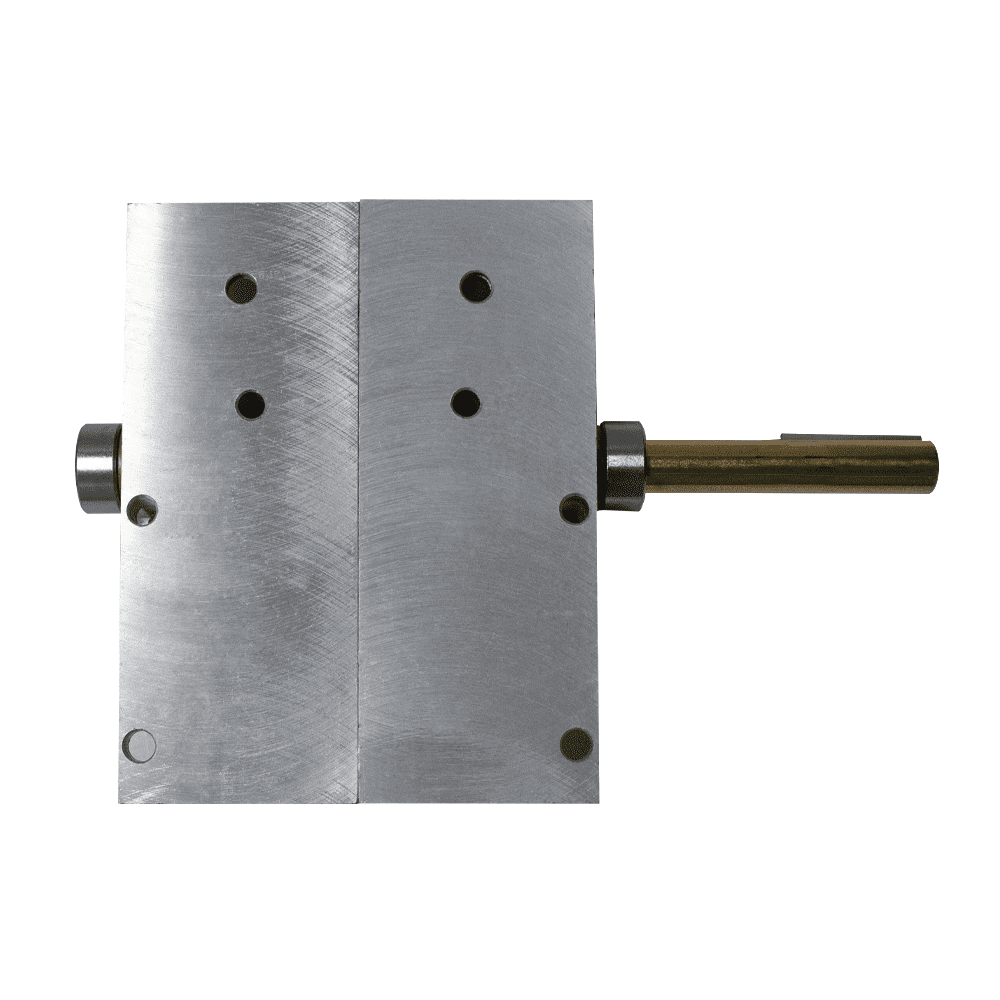

Extended Block Worm Assembly

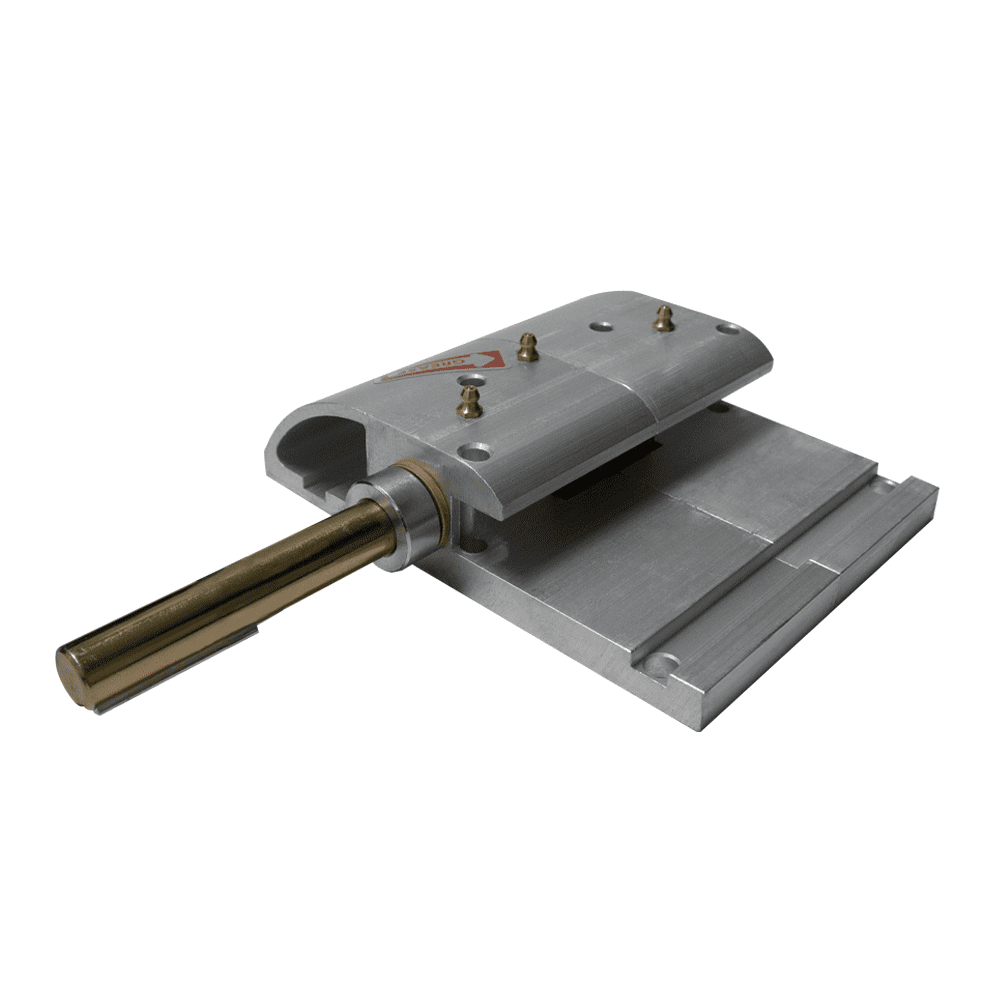

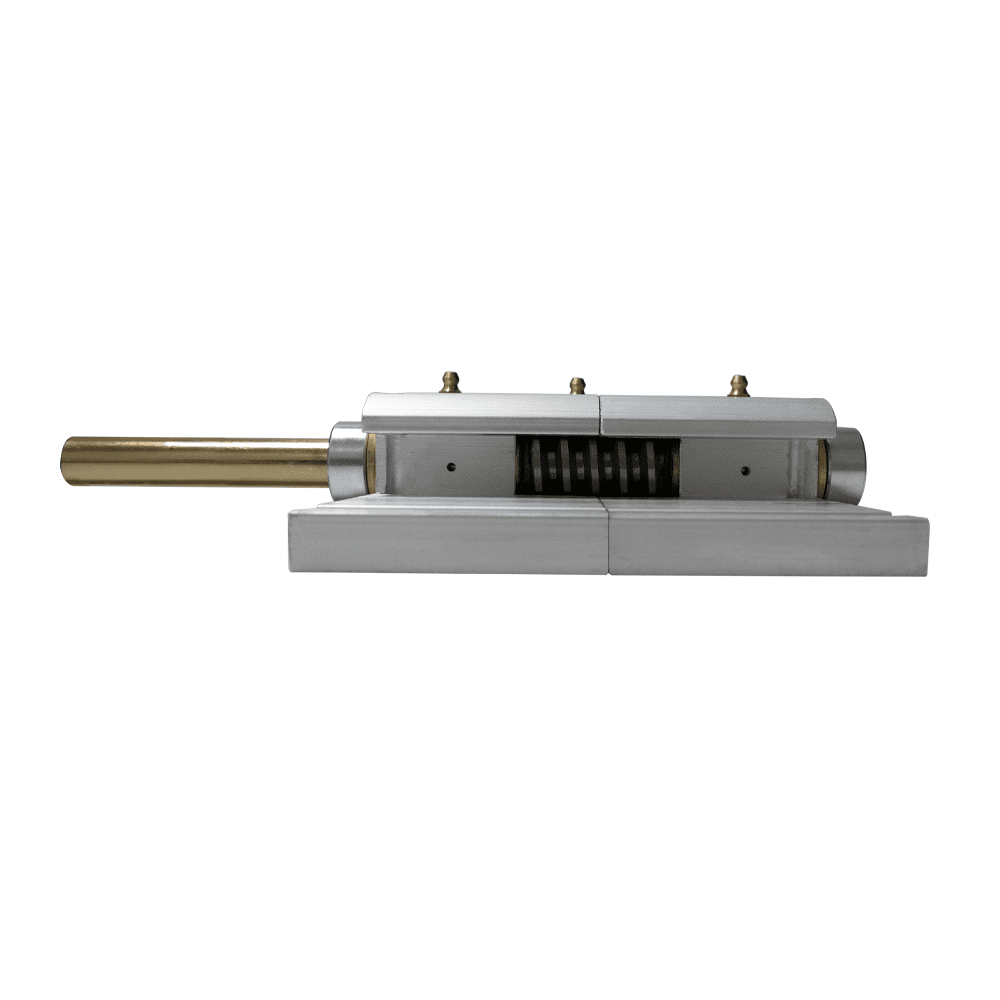

The Extended Block Worm Assembly has a 2-inch bearing block, a worm on a driveshaft, and an aluminum housing with 1/4 inch grease fittings. Attaches directly to the gear plate. The assembly has standard flat-plate mounting holes.

The assembly is fitted with standard flat-plate mounting holes Factory assembled. Blocks are fitted with flange bushings. They have 1/4-inch grease fittings, which can be accessed easily.

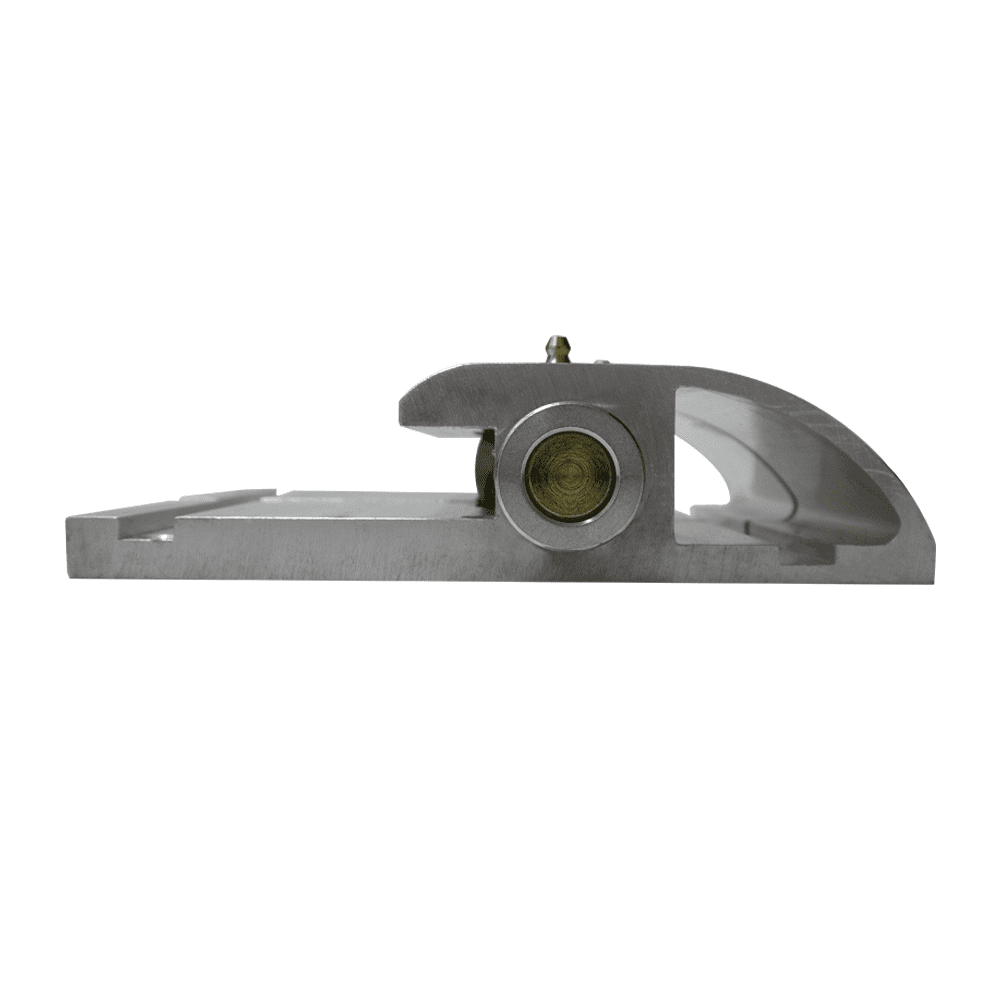

The bronze worm is featured on the Standard and Deluxe series flat-plate boat hoists. On the gear plate, the bronze worm turns the 96-tooth cast iron worm gear. When the flat-plate hoist is assembled, the cast iron worm gear turns the drive pipe.

The Advanced series flat-plate boat hoists feature steel worms. The 96-tooth bronze worm gear that is mounted on the gear plate is turned by the steel worm. Once the flat-plate hoist is fully assembled, the bronze worm gear turns the drive pipe.

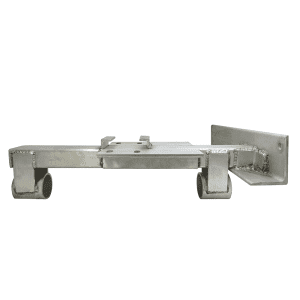

Worm gears are mounted on the gear plate at the top mounting holes. An assembly block is installed around the middle of the gear plate to match up the gear. When the assembly block’s drive shaft rotates, the worm gear inside the assembly block turns the 96-tooth gear. There is a pulley mounted on the drive shaft of the assembly block, and there is a smaller pulley mounted on the drive shaft of the motor, which is mounted at the bottom of the gear plate.

On both pulleys, a belt is installed. The motor rotates its drive shaft in response to the motion of the pulleys on the motor and assembly block, which then turn the worm gear inside the assembly block, which turns the 96 tooth gear. A drive pipe installed through the 96 tooth gear’s bore causes the drive pipe to rotate. If the motor is turning in one direction, or the other, the drive pipe will either raise or lower whatever is attached to it.

There are no mounting fasteners, key stock for the pulley, or pulley included.

Specifications

| Steel Worm | Bronze Worm | |

| Worm Material: | Polished, hardened steel | Hardened bronze (660 or 932) |

| Thread: | Single | Single |

| Thread Direction: | Right hand | Right hand |

| Worm Diameter: | 1 3/4 in. | 1 3/4 in. |

| Worm Length: | 2 in. | 2 in. |

| Worm Bore: | .754 in. | .754 in. |

| Driveshaft Material: | Stress proof steel | Stress proof steel |

| Driveshaft Length: | 11 3/4 in. | 11 3/4 in. |

| Driveshaft Diameter: | .746 in. | 746 in. |

| Grease Fittings: | 3 | 3 |

| Grease Fitting Size: | 1/4 in. | 1/4 in. |

| Collar Size: | 1 1/4 in. x 1 1/4 in. x 1/2 in. | 1 1/4 in. x 1 1/4 in. x 1/2 in. |

| Collar Amount: | 2 | 2 |

| Collar Set Screw Size: | 5/16 in. | 5/16 in. |

The Boat Hoist USA brand offers machine parts used exclusively in the Boat Hoist USA brand flat-plate hoist. BH-USA brand machined parts should NEVER be used with any other brand flat-plate hoist or machined parts. Any individual machine part or re-built/repaired flat-plate hoist is not warranted by BH-USA. Lift-Tex Inc. assumes no liability for damage to person or property caused by the re-building of a flat plate hoist, regardless of its brand. BH-USA sells non-returnable, non-warrantable machine parts. The user is solely responsible for any machine part purchased and used by them. BH-USA does not guarantee that any individual machined part will solve an existing problem or function as designed. BH-USA recommends that you purchase a new flat-plate hoist that has been built and tested on site at BH-USA rather than trying to repair an existing hoist.

Product Overview

{{dc:woocommerce:product_short_description}}