Swaged Loop Galvanized Steel Cable

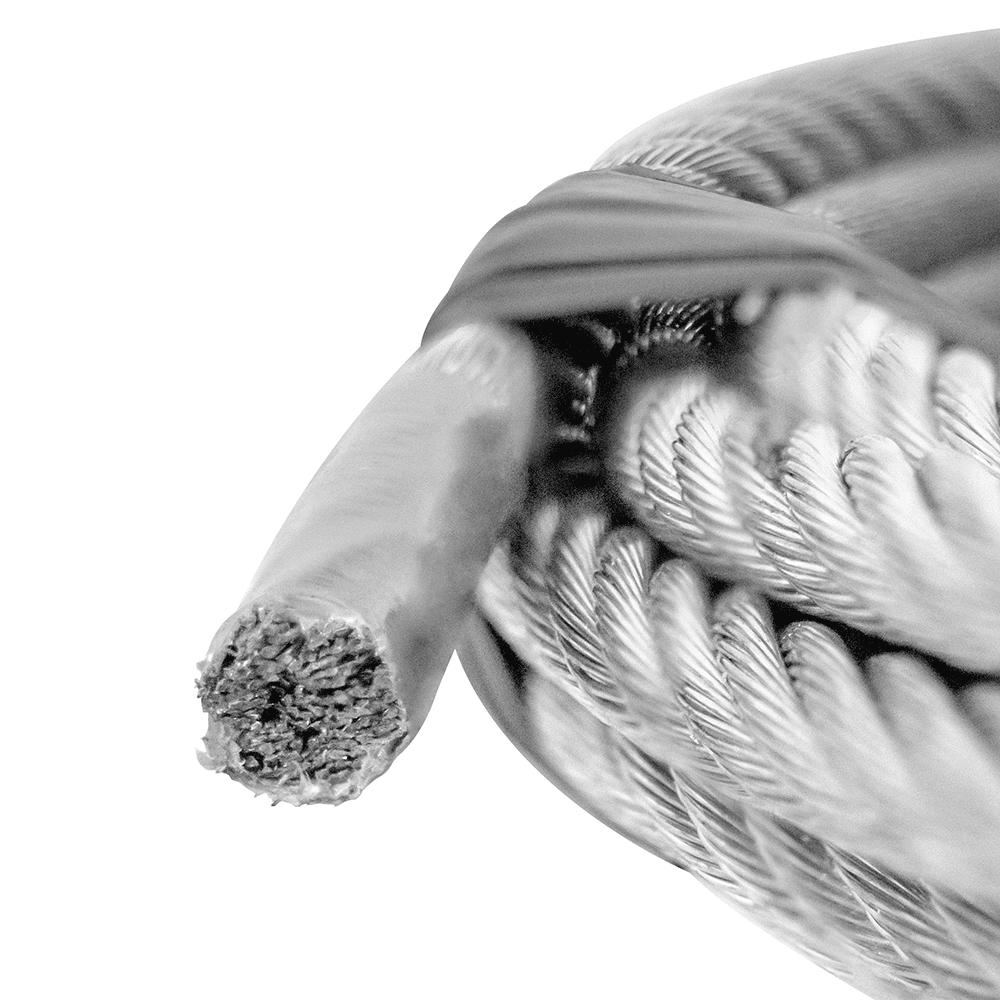

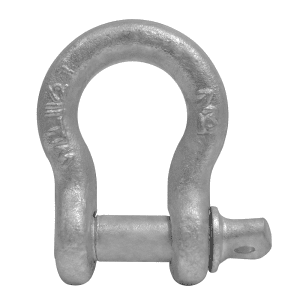

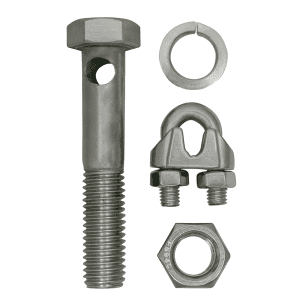

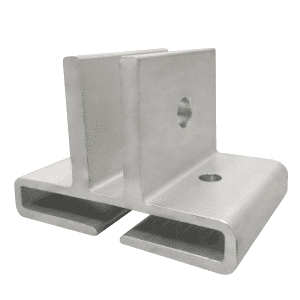

The Swaged Loop Galvanized Steel Cable is prefabrication at the factory with one end having a thimble and wire rope clip installed. The cable is left untouched on the opposite side. Made from hot-dipped galvanized steel cable. Most commonly used in fresh water boat lifts.

Top Features:

- Flexibility: Its 7 x 19 strand construction has flexibility to use sheaves and cable winders easily.

Cable Selection:

- Smart Selection: When picking a wire rope for boat lifts, focus on the Safe Working Load (SWL) rather than just the breaking strength.

Size Matters:

- Cable: To choose the right cable size, consider the total weight you’re lifting, including the boat, cradle, and bunks. BH-USA recommends a 5:1 safety factor.

- Caution: At least 4 drops for boat lift applications.

Maintenance Tips:

- Conditions: Best suited for freshwater applications; for salty adventures, opt for stainless steel due to its superior corrosion resistance.

- Periodic Checks: Regular inspections and some TLC go a long way. Lubricate those ropes, avoid shock loads, and keep an eye out for any signs of wear and tear.

- Caution: Responsibility shifts to users for determining working load limits based on real-world conditions.

Specifications

| Lift Size | 1 Part Straight Line | 2 Part Compounded |

| 2,800 lbs. | 3/16 in. | 3/16 in. |

| 4,500 lbs. | 1/4 in. | 3/16 in. |

| 6,000 lbs. | 5/16 in. | 1/4 in. |

| 9,000 lbs. | X | 1/4 in. |

| 10,000 lbs. | X | 1/4 in. |

| 13,000 lbs. | X | 5/16 in. |

| 16,000 lbs. | X | 3/8 in. |

| 24,000 lbs. | X | 3/8 in.* |

The first step in deciding what size wire rope is required for your lift is to determine the total weight to be lifted which will include the “wet” weight of the boat, the maximum estimated cargo that could be put in the boat during the lift, and the weight of the lifting cradle

- Boat

- Fuel

- Water (Ballast, live well, potable, etc.)

- Any cargo items in the boat (Note: There should never be people in the boat while being lifted.)

- Boat cradle and bunks

The boat weight specified by a manufacturer is typically the “dry” weight of the boat. To get the “wet” weight, you must include the weight of the fuel (gasoline is 6.30 lb/US gal and diesel is 6.94 lb/US gal), the weight of any water (8.34 lb/US gal) that may ever be present in the boat and the estimated weight of the possible cargo (ie – coolers, skis, etc.).

Cable Ratings

| Cable Size | Cable Material | Lifting Capacity | Min. Breaking Strength | Safe Working Limit | Best Water Type |

| 3/16 in. | Stainless | 1,050 lbs. * | 3,700 lbs. | 925 lbs. | Saltwater |

| 3/16 in. | Galvanized | 925 lbs. * | 4,200 lbs. | 1,050 lbs. | Freshwater |

| 1/4 in. | Stainless | 1,750 lbs. * | 6,400 lbs. | 1,600 lbs. | Saltwater |

| 1/4 in. | Galvanized | 1,600 lbs. * | 7,000 lbs. | 1,750 lbs. | Freshwater |

| 5/16 in. | Stainless | 2,450 lbs. * | 9,000 lbs. | 2,250 lbs. | Saltwater |

| 5/16 in. | Galvanized | 2,250 lbs. * | 9,800 lbs. | 2,450 lbs. | Freshwater |

| 3/8 in. | Stainless | 3,600 lbs. * | 12,000 lbs. | 3,000 lbs. | Saltwater |

| 3/8 in. | Galvanized | 3,000 lbs. * | 14,400 lbs. | 3,600 lbs. | Freshwater |

* – Use a minimum of 4 drops for boat lift applications

NOT FOR LIFTING HUMANS

No product can operate indefinitely at its rated capacity. Wire rope and Cable must be inspected regularly for any deterioration which may result in the loss of original strength. Users must determine whether further use of the rope would constitute a safety hazard to life or property. Lubricate operating ropes regularly. Keep out from under any raised loads and keep out of the line of force of any load.

AVOID SHOCK LOADS.

Due to the uncontrollable situations in which this cable is used after the purchase, BH-USA cannot warranty or be held liable for cable past the purchase date. It is the responsibility of the ultimate user to determine a working load limit for each application. Many factors should be considered: included among, but not limited to, loads applied, speed of operation, acceleration or deceleration, length of rope or cable, shock loads, abrasion, corrosion, number, size, condition, and location of drums and sheaves, facilities for inspection, and the danger to life and property should a rope or cable break. Wire Ropes and Cables must be stored, used, lubricated, and maintained in accordance with normal safety standards; and must be properly designed, maintained, and operated. Inspect regularly.

Do not kink, knot, or crush. Do not ever use wire rope sold by or made by BH-USA to lift humans in any way.

Product Overview

{{dc:woocommerce:product_short_description}}

Product Guides

You may also like…

-

Pre-Cut Galvanized Steel Cable

$30.17 – $87.83 Select options This product has multiple variants. The options may be chosen on the product page -

316 Stainless Steel Cable

$174.13 – $15,777.00 Select options This product has multiple variants. The options may be chosen on the product page -

Swaged Loop 316 Stainless Steel Cable

$13.20 – $209.79 Select options This product has multiple variants. The options may be chosen on the product page -

Pre-Cut 316 Stainless Steel Cable

$27.20 – $246.10 Select options This product has multiple variants. The options may be chosen on the product page