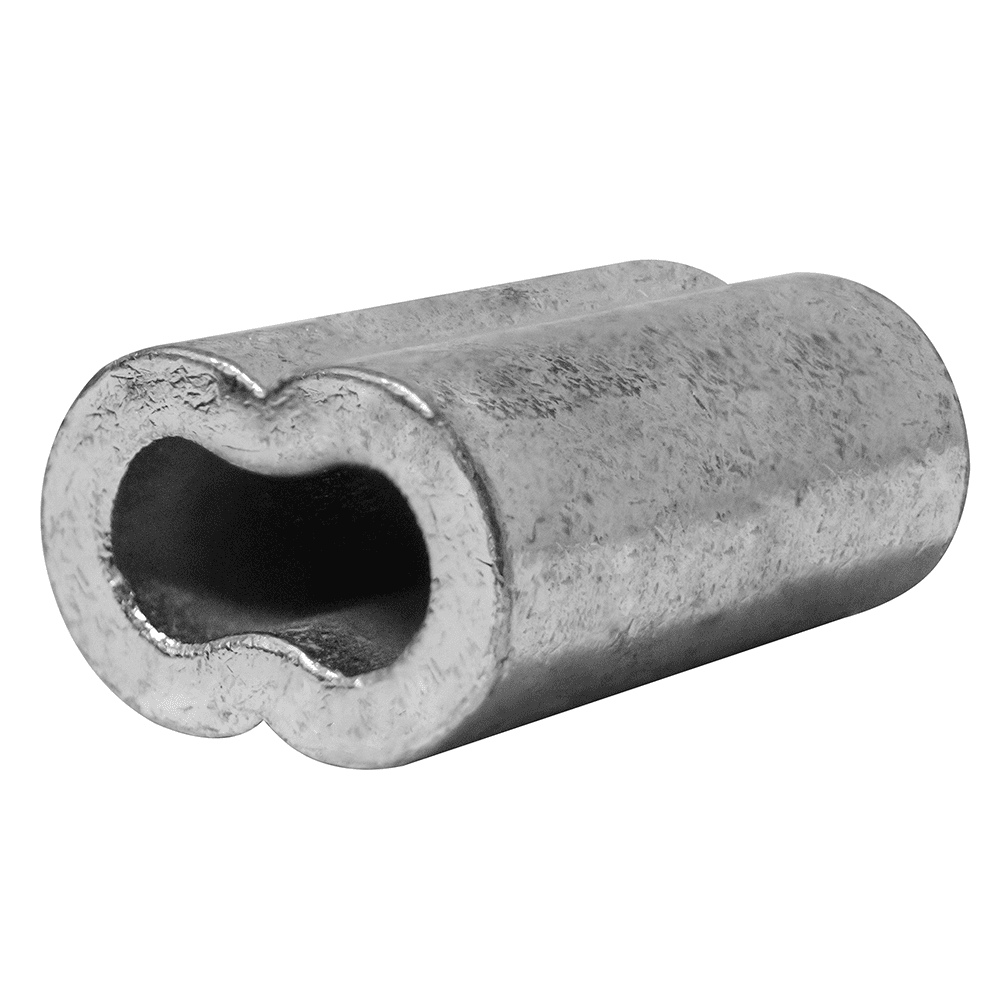

Zinc Coated Copper Sleeves

Zinc Coated Copper Sleeves are essential parts used to securely end cables, commonly seen in various applications needing strong wire connections. Shaped like an hourglass, they grip wire ropes tightly, reducing the risk of slipping or breaking. To install them, you typically use a wire rope crimper, ensuring a sturdy and lasting connection. These sleeves meet US standards and work well in marine settings because they have a zinc coating that fights corrosion.

Swaging is the best way to finish wire ropes with these sleeves, and BH-USA suggests using 7 x 19 aircraft cables for boat lifts. But remember, always factor in a 5:1 safety margin when figuring out how much weight they can handle. These sleeves aren’t meant for lifting people or being in saltwater for a long time. BH-USA can’t guarantee or be responsible for rigging after purchase, so users need to figure out the right weight limit and follow safety rules for each job. By doing this, users can ensure safe and reliable wire rope connections using Zinc Coated Copper Sleeves.

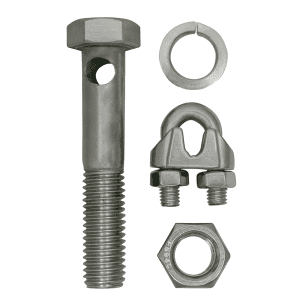

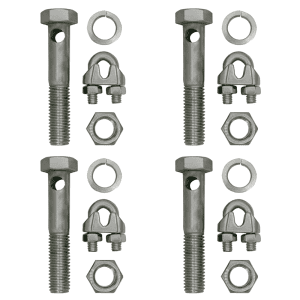

Product Overview

{{dc:woocommerce:product_short_description}}

Product Guides

You may also like…

-

Stainless Wire Rope Thimbles

$3.22 – $4.78 Select options This product has multiple variants. The options may be chosen on the product page